Achievements of MH21 over 18 years

The Research Consortium for Methane Hydrate Resources in Japan (MH21), established in July 2001 by the Ministry of Economy, Trade, and Industry (METI), had concluded studies of Japan's Methane Hydrate R&D Program that ended in March 2019. The 18-year program generated numerous outcomes, for example, i) the discovery of methane hydrate concentrated zones (MHCZs), which are areas of highly concentrated methane hydrate deposits in sandy layers of the eastern Nankai Trough, and ii) onshore and offshore production tests to verify the depressurization method, which does not require input of artificial thermal energy, as an efficient methane hydrate dissociation technique.

However, there is still a long way to go to achieve the project’s goal of introducing marine methane hydrates into Japan's domestic resource portfolio.

After a review of past accomplishments and remaining issues, METI decided to continue the methane hydrate research and development (R&D) and launch a new phase (Phase Four) of the program that covers the Japanese fiscal years of 2019–2022 (from April 2019 to March 2023). The MH21-S consortium has begun executing the part of the plan covering the pore-filling type of methane hydrate.

Overview of Each Phase

Phase 1(FY2001 - FY2008)

MH21 conducted various surveys in the eastern Nankai Trough area and revealed the existence of methane hydrate-concentrated zones (MHCZs). In addition, the volume of gas trapped in the area was estimated.

In a world-first attempt, MH21 succeeded in continuously producing methane gas from methane hydrate-bearing sediment by dissociating methane hydrates in the Mallik field in the Northwest Territories of Canada. Both the hot water circulation method (2002) and the depressurization method (2007 and 2008) were successfully conducted to produce methane gas, and the depressurization method was proven to be an effective production method that could be utilized in future.

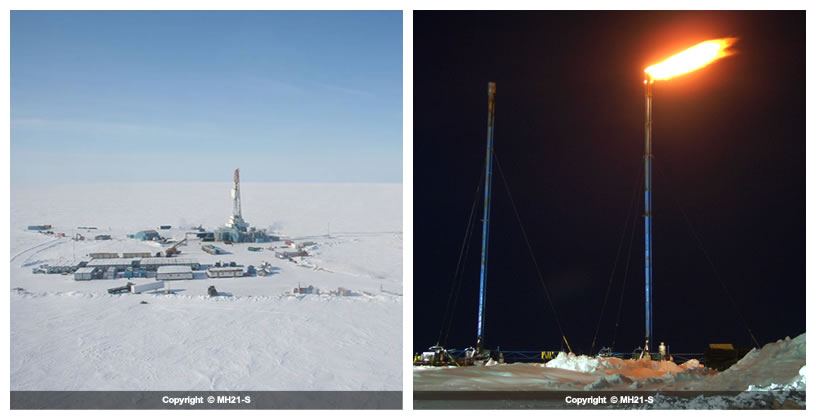

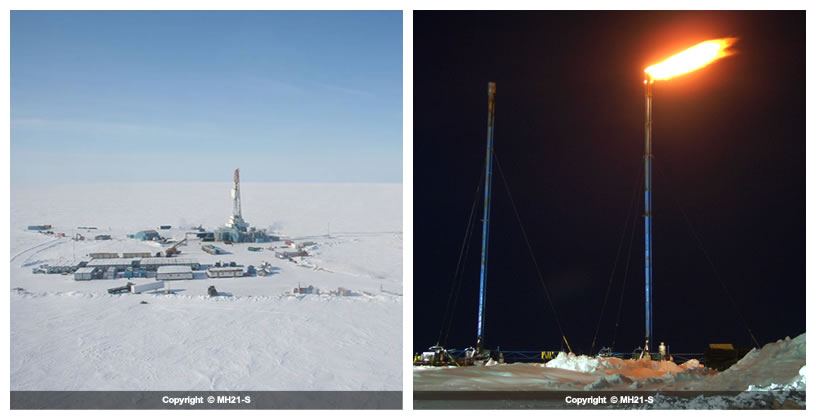

Left. Far view of production test site of second onshore production test

Right. Flare of methane gas on second onshore production test

More information: Phase 1 Comprehensive Report of Research Results(FY2001-2008)

Phase2(FY2009 - FY2015)

The first offshore production test conducted in 2013 in the Eastern Nankai Trough area was the world’s first attempt to extract gas from marine methane hydrate deposits. The test was terminated earlier than expected due to sand production, however, it verified the fact that the depressurization method can be applicable to offshore wells, and produced 119,000 m3 of methane gas during the six-day production period.

However, a number of technical challenges surfaced such as managing separate downhole gas-water, and how to manage the risks of carrying out an emergency disconnect.

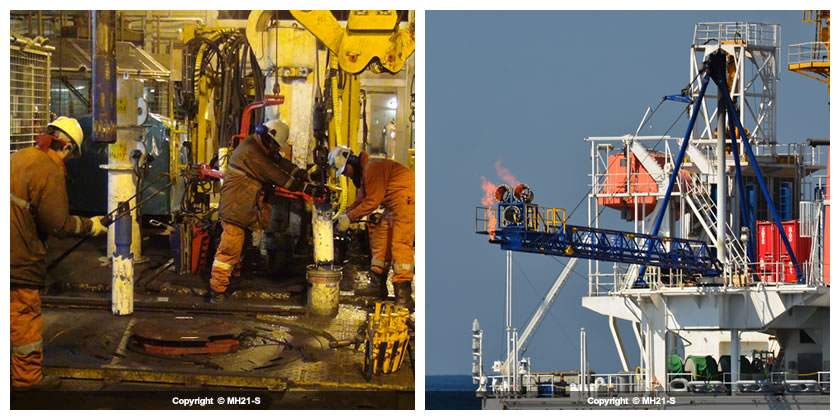

Left. Working at drill floor

Right. Flare

Phase3(FY2016 - FY2018)

After development and implementation of certain advanced technologies aimed at enabling more stable operations, the second offshore production test was carried out in 2017 in the same region. Twelve days of flow was realized at the first well in spite of intermittent sand-related issues. In the second well, with reinforced sand mitigations, the flow period was extended to a total of 24 days despite being interrupted by rough weather conditions and series flow assurance issues. The total volume of gas produced reached 263,000 m3 . The operation lasted a total of 36 days at two boreholes. Large amounts of information crucial to the estimation of long-term behavior was obtained. A number of unpredictable technical issues surfaced, however, such as the difference between results predicted by the model and actual gas production behavior.

As the final phase of the R&D Program that commenced in FY 2001, MH21 has compiled the results and outcomes of the program here.

Furthermore, Japan and the U.S. Partners (National Energy Technology Laboratory (NETL) of the US Department of Energy (DOE)) collaboratively conducted technical studies, selection of testing sites, and preparation work for field activities. In December 2018, we completed stratigraphic test well drilling in Alaska.

More information: Comprehensive Report of Phase 2 & 3 Research Results(FY2009-2018)

Methane Hydrate Production Tests

First Onshore Production Test(December 2001 - March 2002)

The first onshore production test was carried out at the Mallik site in the Mackenzie Delta in the Northwest Territories of Canada.

This test was carried out as a collaborative research project among five countries (Japan, Canada, USA, India, and Germany) and seven research institutes (the former Japan National Oil Corporation – the predecessor of JOGMEC, Geological Survey of Canada (GSC), US Department of Energy (DOE), US Geological Survey (USGS), German Research Center for Geosciences (GFZ), Indian Ministry of Petroleum and Natural Gas – Oil and Natural Gas Corporation (ONGC) in India, and Project of BP-ChevronTexaco Mackenzie Delta Joint Venture).

The “Hot water circulation method” – a type of heating method – was selected to produce methane gas from methane hydrate layers in this test. It succeeded in producing approximately 470 m3 of methane gas over the five-day production period. This was the first time in the world that methane gas had ever been produced from methane hydrate layers.

Mallik site for onshore production test

Second Onshore Production Test (April 2007 (first winter) and March 2008 (second winter))

MH21 carried out the second onshore production test at the Mallik site, where they tested the hot water circulation method in 2002.

This test was conducted twice, once in 2007 (the first winter) and again in 2008 (the second winter).

The depressurization method in the field was executed by draining water in the well using a pump to alleviate the pressure on the methane hydrate layers.

In the First Winter Test in 2007, methane gas was collected from methane hydrate that had dissociated as a result of the depressurization method. However, since methane hydrate layers are unconsolidated sediments, sand was also collected (sand production) along with methane gas and water, and the sand stalled the pump. As a result, the test had to stop 12.5 hours after it began.

Although the test was terminated within a very short time frame, it was the first time in the world that methane gas had ever been successfully collected from methane hydrate layers using the depressurization method.

After developing measures to prevent sand production, MH21 reattempted the depressurization method-based production test again in the Second Winter Test in 2008. In this test, MH21 achieved continuous production over a period of approximately six days. The volume of methane gas produced during the test period was approximately 13,000 m3 , significantly larger than the approximately 470 m3 produced in the first onshore production test. This demonstrated that the depressurization method is effective for producing methane hydrate.

Left. Far view of production test site of second onshore production test

Right. Flare of methane gas of second onshore production test

The following summarizes the contents and significance of the second onshore production test.

Yamamoto, K., and Dallimore, S. R. (2008): Aurora-JOGMEC-NRCan Mallik 2006-2008 Gas Hydrate Research Project Progress. Fire in the Ice, Methane Hydrate Newsletter, National Energy Technology Laboratory, Summer 2008.

More information: “ 6. Achievements of the Onshore Gas Hydrate Production Test” on page 33 in the Comprehensive Report of Research Results

First Offshore Production Test (February 2012 - April 2013)

The first offshore production test in the eastern Nankai Trough in 2013 was a world-first attempt to produce gas from a methane hydrate deposit below the seafloor. Large depressurization and subsequent gas production was successfully implemented using a floating drilling vessel, and methane hydrate dissociation and continuous production of methane gas was achieved for a period of six days. It resulted in the production of 119,000 m3 of gas.

However, this test was terminated by sudden and severe sand production, and as a result, stability of gas production was not able to be successfully proven. The large amount of data acquired shed light on the relationship between methane hydrate dissociation and reservoirs characteristics, however, the data was not sufficient to enable prediction of the long-term behavior of gas production. Furthermore, a number of technical challenges surfaced such as how to control sand, separate formation of downhole gas-water, and how to manage the risks of carrying out an emergency disconnect.

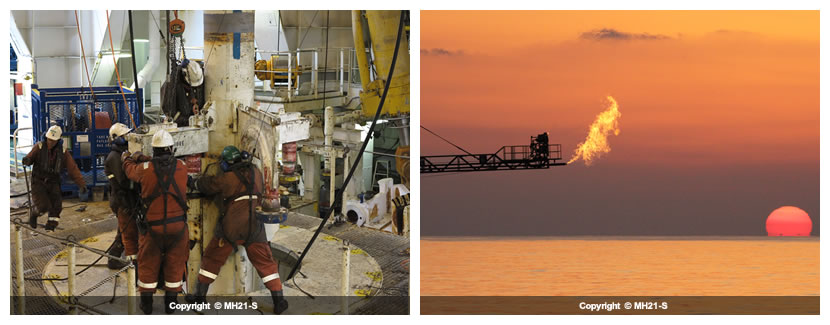

Left. Descent of blowout preventer (BOP)-after arrival at seafloor

Right. Flare at sunset

Second Offshore Production Test(May 2016 - June 2018)

To demonstrate the reliability of countermeasures to the technical challenges that arose, and to acquire data that could facilitate understanding of long-term behaviors, the second offshore production test was carried out at the same region as the first test with the aim of achieving longer-term gas production.

The operation lasted a total of 36 days at two boreholes. In the AT1-P3 well, 12 days of gas production was achieved with 8 MPa drawdown in spite of intermittent sand production. The gas production rate was as low as 3,000-4,000 m3/d and no potential to increase the gas production rate was identified. The water production rate was approximately 80 m3/d.

The following operation in the AT1-P2 well suffered from a higher water rate than expected (300-500 m3/d) as well as a limited drawdown (maximum 5 MPa during stable term), however, a higher gas production rate (10,000 m3/d) was achieved.

Several flow assurance problems due to re-association of methane hydrate in the flowline occurred as a result of insufficient drawdown that made the PT conditions around the seafloor lie within the MH stability condition. A planned disconnect was successfully carried out, and the operation was resumed after re-connection. A total of 36 days of flow was achieved and a large amount of data was acquired as a result of operations carried out at the producer and monitoring holes.

A number of unseen technical issues surfaced such as the difference between results predicted by the model and actual gas production behavior. Accrual of further knowledge about long-term behavior should be critical to resolving those issues going forward.

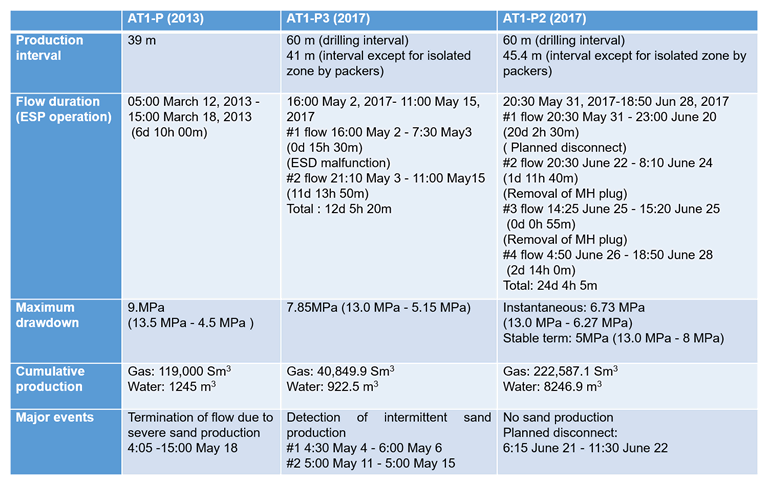

The following summarizes conditions and results of the first and second offshore production tests.

Table 1 Conditions and results of the first and second offshore production tests

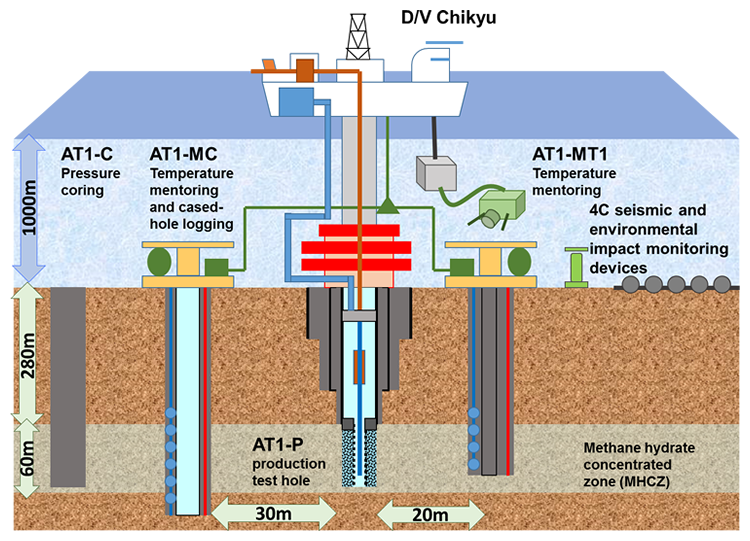

Fig.1 Well configuration of the first test (2013)

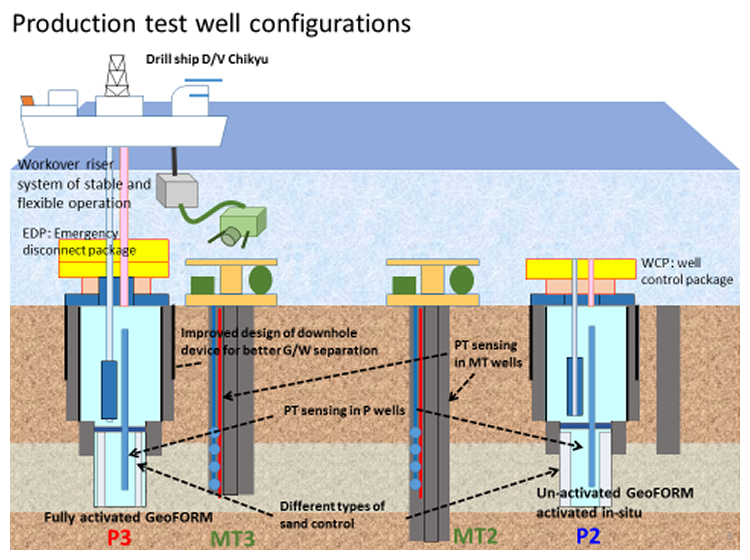

Fig.2 Well configuration of the second test (2017)

More information: “IV.2.2 Overview of Offshore Production Tests and Design Concepts of Used Boreholes” page on Ⅳ‐10 in 1-2.Gas Production Techniques from Methane Hydrate Reservoir

More information: Comprehensive Report of Research Results